Our Captive Motor Laminations unit stands as a pivotal force in our manufacturing capabilities, delivering an impressive output of 1000 tonnes per month. This unit is equipped with cutting-edge machinery, featuring seven precise Japanese high-speed Aida press machines for punching, high-speed slitting lines, and advanced heat treatment facilities. This technological arsenal ensures both efficiency and precision throughout the manufacturing process.

At the heart of our strategy is in-house tool manufacturing, supported by state-of-the-art equipment such as Chevalier imported surface grinders and Mitsubishi wire cut machines.

To underscore our commitment to excellence, we implement rigorous quality control measures, utilizing German magnetic testing instruments, 3D coordinate measuring equipment, and a universal tool microscope. This integrated approach empowers us to maintain control and uphold quality standards at every stage of the production cycle.

From production to quality assurance, our Captive Motor Laminations unit exemplifies a commitment to technological prowess and uncompromising quality, solidifying its position as a cornerstone of excellence within our operations.

AQUA GROUP'S commitment to innovation is showcased through our Research and Development endeavors, garnering recognition such as the top-rank award (2016) from the Bureau of Energy Efficiency for selling the highest number of STAR-RATED pump sets over four consecutive years. The Ministry of Power has also acknowledged our high-efficiency pump sets as a technological innovation.

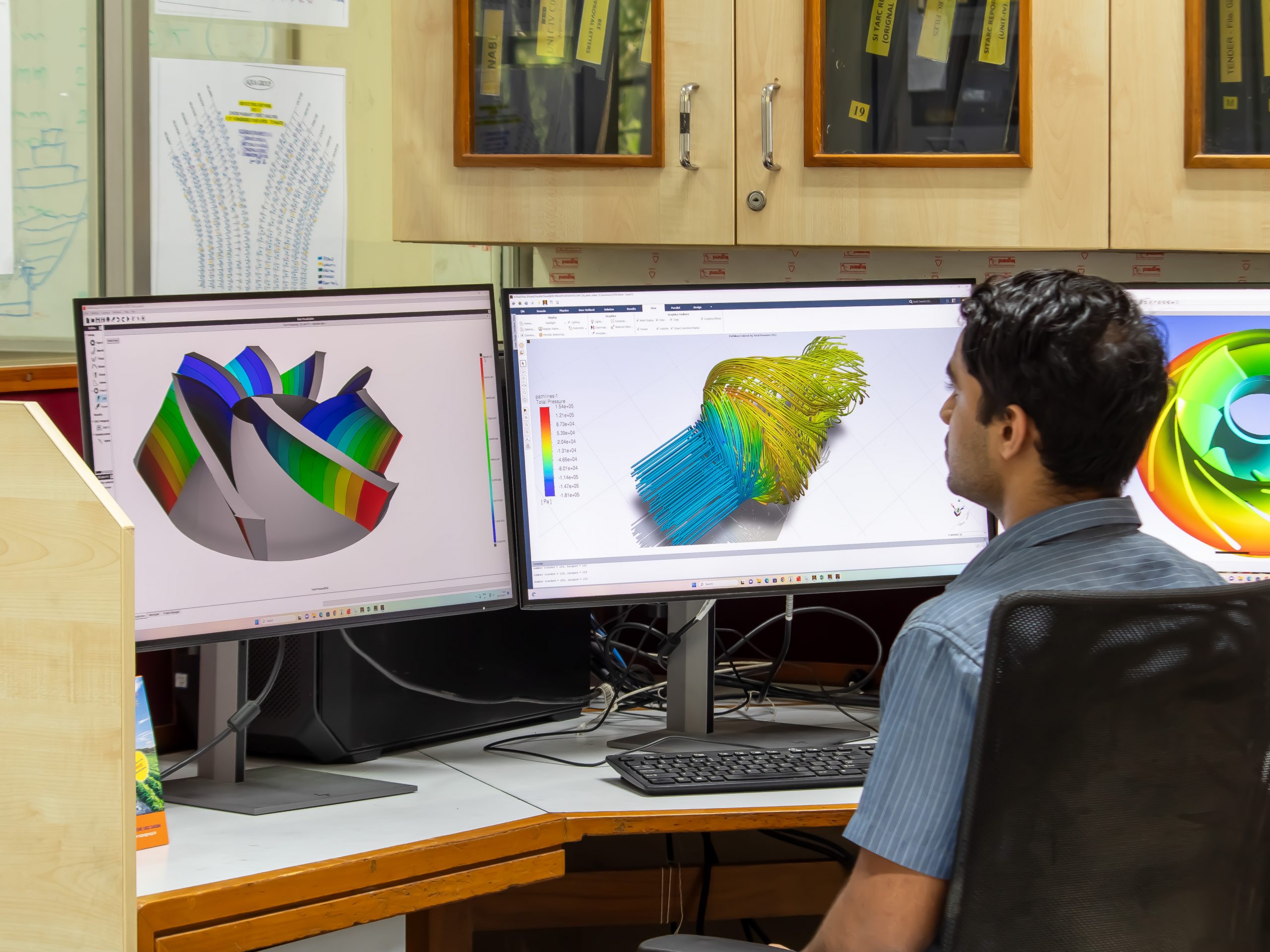

In our pursuit of excellence, we leverage cutting-edge technology and software in our R&D processes. Advanced CAD/CAM tools like Autocad, Solidworks, and Unigraphics aid in creating and introducing new models while seamlessly managing legacy data.

Adhering to international hydraulic efficiency standards, we optimize designs using TurboDesign Suite. To ensure reliability and manufacturability, CAE/CFD tools such as Ansys analyze mechanical and hydraulic components virtually.

Our dedication to innovation extends to 3D printing facilities, enabling rigorous testing of designs before experimental verification. The use of Stratysys 3D printer facilitates rapid prototyping, expediting the development process and ensuring first-time-right designs. These efforts have earned us accolades, demonstrating our commitment to excellence and technological leadership in the industry.

AQUA GROUP has been a trailblazer in the renewableenergy sector since 1992, marked by its pioneering wind farm in Tamil Nadu. With a commitment to green energy, the wind farm exemplifies AQUAGROUP substantial contribution to the sustainable energy landscape. Currently, the group's wind power capacity stands at an impressive 27 Megawatts, utilizing Suzlon, Gamesa, NEPC, and Vestas machines across multiple locations.

This wind farm plays a pivotal role in meeting the entire energy demand of AQUA GROUP'S manufacturing units. The excellence of these sustainability efforts has been duly recognized, culminating in the prestigious Best Performing Wind Farm award from the Indian Wind Power Association in 2023. AQUA GROUP commitment to sustainability is not just a vision but a tangible contribution to a greener future.

AQUA GROUP prioritizes in-house precision machining to ensure outstanding quality and strict adherence to stringent tolerances. Leveraging advanced technology, our high-volume part manufacturing utilizes cells with robotic automation, enhancing overall productivity. Renishaw Touch probes and a tool measurement system are employed to guarantee improved machining accuracy and quality. The Renishaw ballbar system facilitates machine condition monitoring, contributing to consistently high part quality.

Auto offset correction eliminates manual intervention, ensuring uncompromised part quality through direct tool wear correction. Our CNC Grinding process, complemented by auto gauging, achieves the highest accuracy with super-finished parts. The auto-run-out removal machine maintains quality standards for rotating parts. The integration of a Coordinate Measuring Machine further underscores AQUA GROUP'S commitment to precision and stringent quality control throughout the machining process.